Samsung LCD Display & Frame Assembly Experts | Luoyi Technology

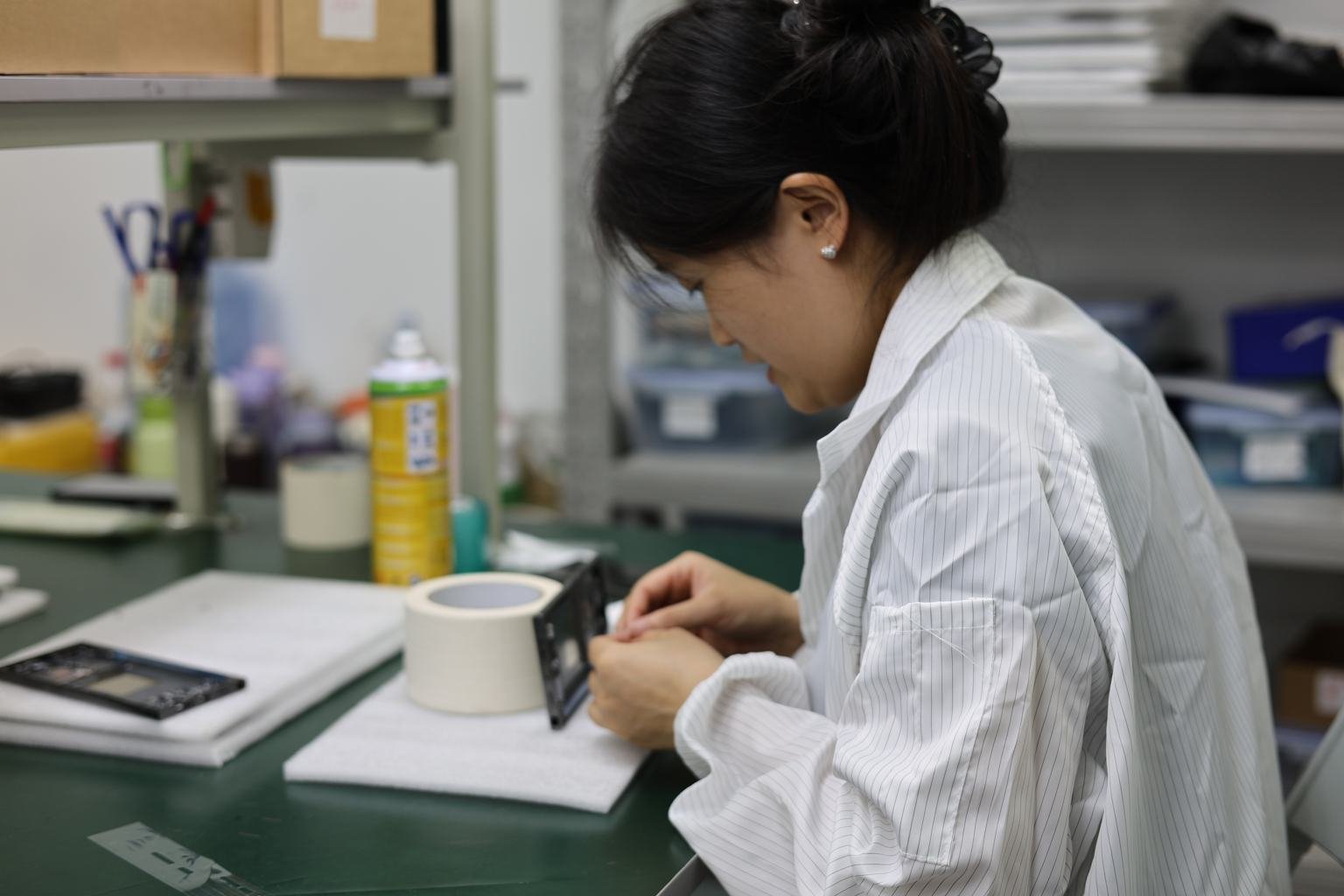

Headquartered in Hong Kong, Luoyi Technology Co., Ltd. specializes in high-precision assembly services for Samsung mobile phone LCD displays and mid-frames. The company has a highly skilled and experienced engineering team equipped with modern assembly equipment, committed to providing customers with high-standard, high-consistency product solutions.

Description

Luoyi Technology (Hong Kong) Co., Ltd. combines Hong Kong’s logistical advantages with deep manufacturing know-how to deliver premium display services for Samsung flagship devices. From initial incoming inspection to final packing and shipping, our teams work to ensure each unit meets strict performance and mechanical standards. Early validation and controlled assembly minimize rework and accelerate time-to-market for our partners. In every project we emphasize repeatable processes and measurable outcomes, which is why our customers rely on us for Samsung LCD assembly on both trial runs and mass orders.

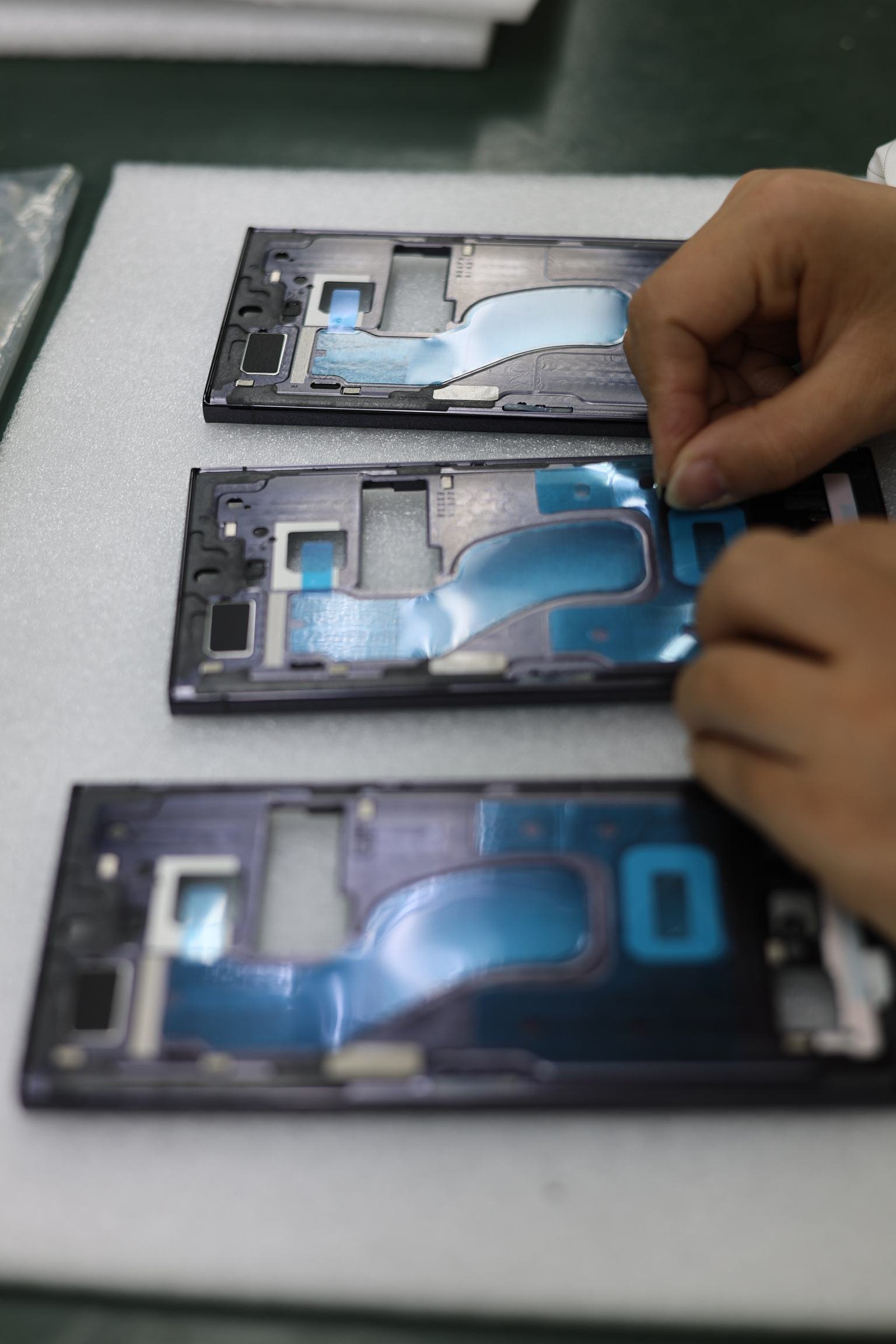

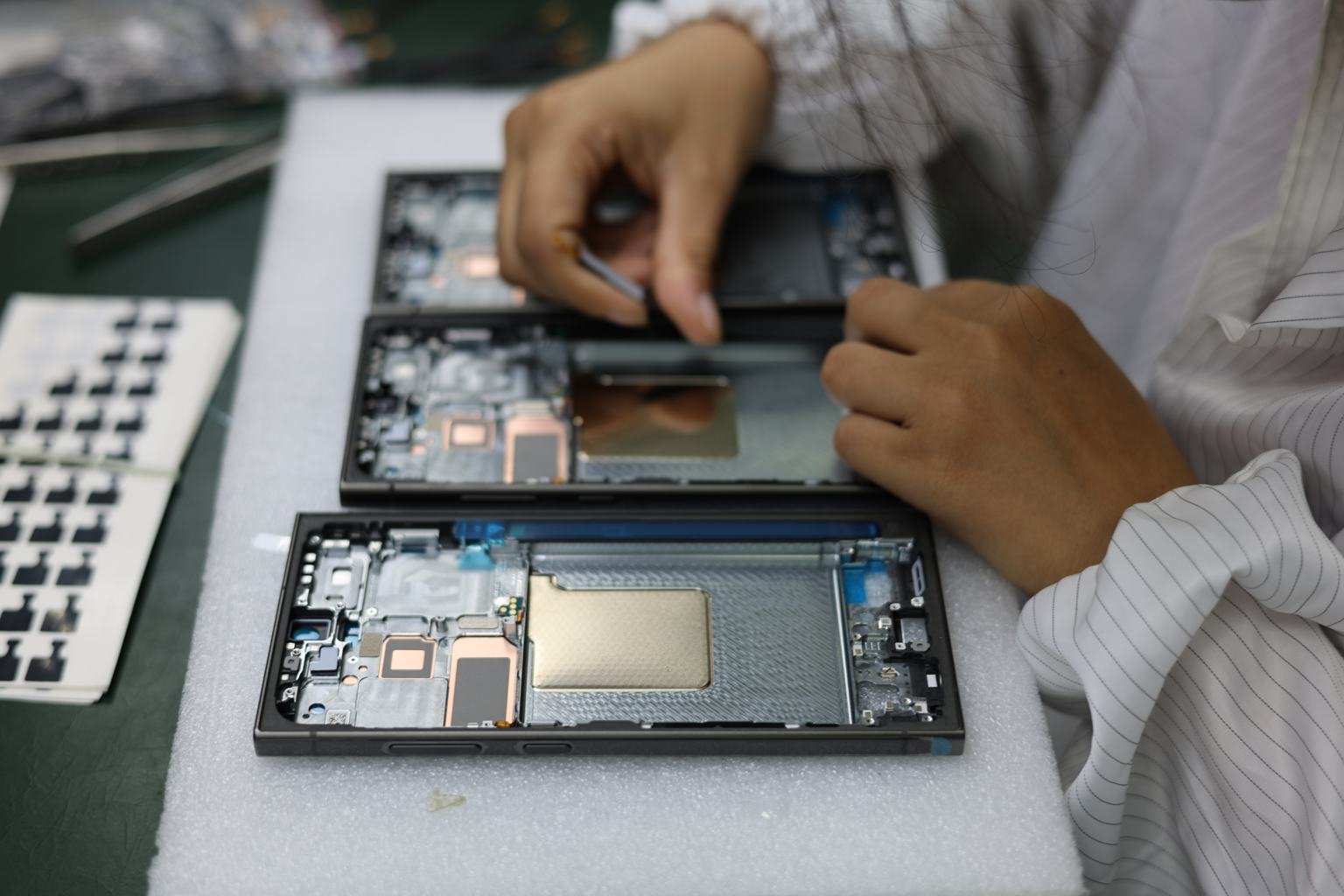

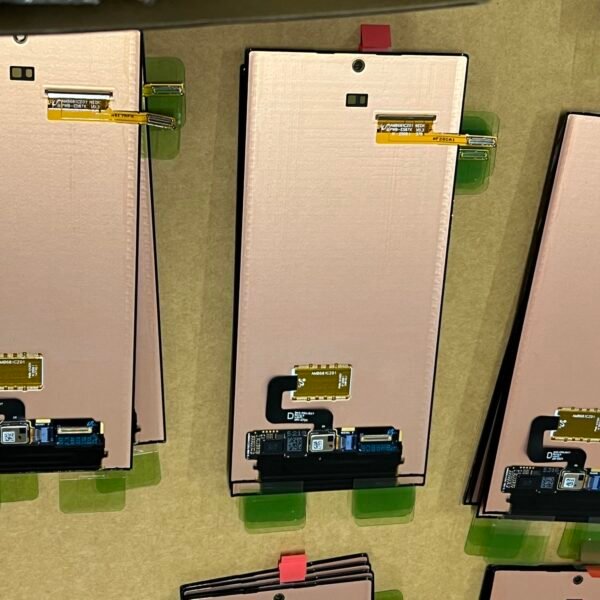

Our service portfolio covers precise panel-to-frame bonding, optical calibration, edge sealing, alignment verification, and final function checks. We operate specialized clean production lines and calibrated tooling that ensure consistent tolerances across batches. For customers who need integrated structural solutions, our engineering group provides advanced jig design and process flow optimization to reduce waste and boost yield. We are also an established provider of Samsung frame assembly, able to adapt to multiple mid-frame variants and maintain exact mechanical clearances required by OEM specifications.

Being located in Hong Kong gives us strong advantages in procurement, international logistics, and rapid sample exchange. We support direct client-supplied components as well as full-service projects where Luoyi sources compatible parts, conducts BOM validation, and executes final assembly. Clients often choose our LCD module assembly Hong Kong services because we blend technical rigor with flexible scheduling — ideal for repair networks, regional distributors, and device manufacturers who need consistent, traceable output.

Manufacturing, Equipment and Process Control

Manufacturing, Equipment and Process Control

Our factory uses a mix of automated and semi-automated stations that maximize throughput while preserving the fine control needed for fragile displays. Key process stages include robotic or precision manual bonding, UV curing or thermal lamination depending on materials, automated optical inspection (AOI) for defect detection, and a final functional test bench that simulates real-world usage. We log machine parameters, operator IDs, and environmental conditions for each lot to help customers analyze yields and spot trends.

To meet strict tolerance and cosmetic expectations, our technicians perform multi-step alignment against reference fixtures and optical targets. When color calibration is required, we apply spectroradiometric profiling to standardize appearance across panels. These detailed controls are part of how we deliver consistent results for Samsung LCD assembly even as volumes scale.

Capacity, Flexibility and Turnaround

Our production lines are structured to support both small pilot runs and sustained volumes. Typical daily capacity ranges from several hundred to one thousand completed assemblies, depending on model complexity and tested configurations. For urgent needs, we provide prioritized scheduling and dedicated lines to compress lead times without compromising quality. Our logistics team coordinates packaging options and international shipment routes so clients receive finished assemblies on predictable schedules. Throughout this process, the goal remains the same: deliver finished modules with stable performance and a clean, factory-like fit — the kind of quality expected from professional Samsung frame assembly.

Quality Management and Traceability

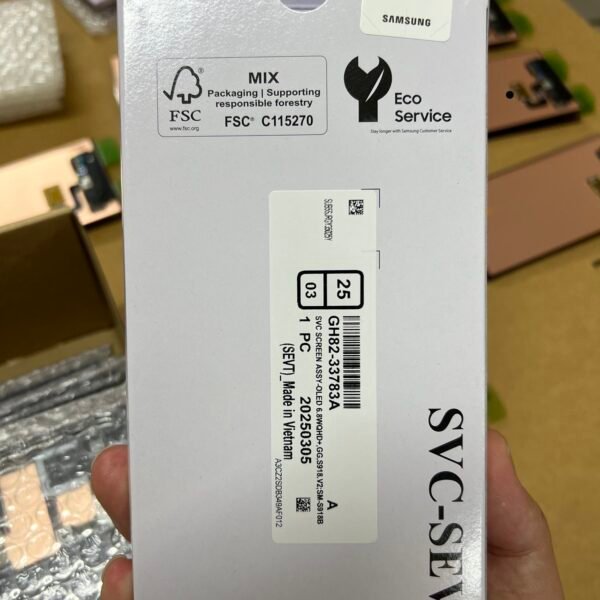

Quality is embedded in our workflow. Incoming inspection validates incoming QC reports and verifies serial data; inline checks prevent defective parts from progressing deeper into production. Each finished unit is labeled and associated with batch data, test reports, and operator traceability. These records enable efficient root-cause analysis when issues arise and support warranty handling or aftermarket servicing. Clients particularly value this level of documentation when integrating our production into larger supply chains or warranty programs, which is a core value we bring to every LCD module assembly Hong Kong engagement.

Global Partnership and After-sales Support

Global Partnership and After-sales Support

We serve partners across Europe, North America, the Middle East, and Southeast Asia. Our commercial teams speak multiple languages and are experienced in export compliance, packaging standards, and customs documentation. Beyond manufacturing, Luoyi offers product reliability testing, drop and mechanical shock simulations, and sample validation programs to help partners shorten certification timelines. We also offer flexible commercial terms for long-term collaboration and can scale commitments as demand grows.

Typical Use Cases

- OEM and ODM clients needing small to mid-volume runs for regional launches;

• Repair centers and parts distributors seeking ready-to-install modules for aftermarket replacement;

• Product designers requiring pre-production prototypes with near-production-level assembly quality;

• Quality-driven resellers who want traceable, documented components for after-sales support.

Final Assurance & Invitation

At Luoyi Technology we don’t treat assemblies as commodity work — we treat them as critical components of your customer experience. Our teams are focused on delivering consistent mechanical fit, dependable electrical function, and cosmetic integrity every time. If your project requires a partner who understands Samsung-grade tolerances and can deliver on schedule, we’re ready to help. Reach out to discuss technical requirements, sample programs, or volume quotes and see how our Samsung LCD assembly capabilities can reduce risk and accelerate your product plans.

We also welcome inquiries about more advanced integration, including custom frame modifications, additional component bonding (e.g., metal shields or shielding gaskets), and extended traceability services that align with your warranty and service models. For durability, logistics, or cost-optimization questions, Luoyi is prepared to provide concrete data and actionable recommendations drawn from long-term production experience with Samsung frame assembly projects.

We also welcome inquiries about more advanced integration, including custom frame modifications, additional component bonding (e.g., metal shields or shielding gaskets), and extended traceability services that align with your warranty and service models. For durability, logistics, or cost-optimization questions, Luoyi is prepared to provide concrete data and actionable recommendations drawn from long-term production experience with Samsung frame assembly projects.

Partner with Luoyi Technology and benefit from a Hong Kong-based service that blends engineering excellence, reliable manufacturing, and attentive customer care. If you prefer a localized solution with global reach, our LCD module assembly Hong Kong service is designed to meet those expectations.

Reviews

There are no reviews yet.