High-Quality Samsung LCD Assembly | Luoyi Technology

Headquartered in Hong Kong, Luoyi Technology Co., Ltd. specializes in high-precision assembly services for Samsung mobile phone LCD displays and mid-frames. The company has a highly skilled and experienced engineering team equipped with modern assembly equipment, committed to providing customers with high-standard, high-consistency product solutions.

Description

Luoyi Technology (Hong Kong) Co., Ltd. combines Hong Kong’s strategic logistics advantage with years of hands-on engineering experience to deliver premium integrated display and mid-frame solutions for global customers. We serve OEM distributors, repair centers, and international trading firms with transparent processes and measurable outcomes. For customers who need expert integration, our team specializes in Samsung LCD assembly, offering both assembly-only and full turnkey service options to match your commercial needs.

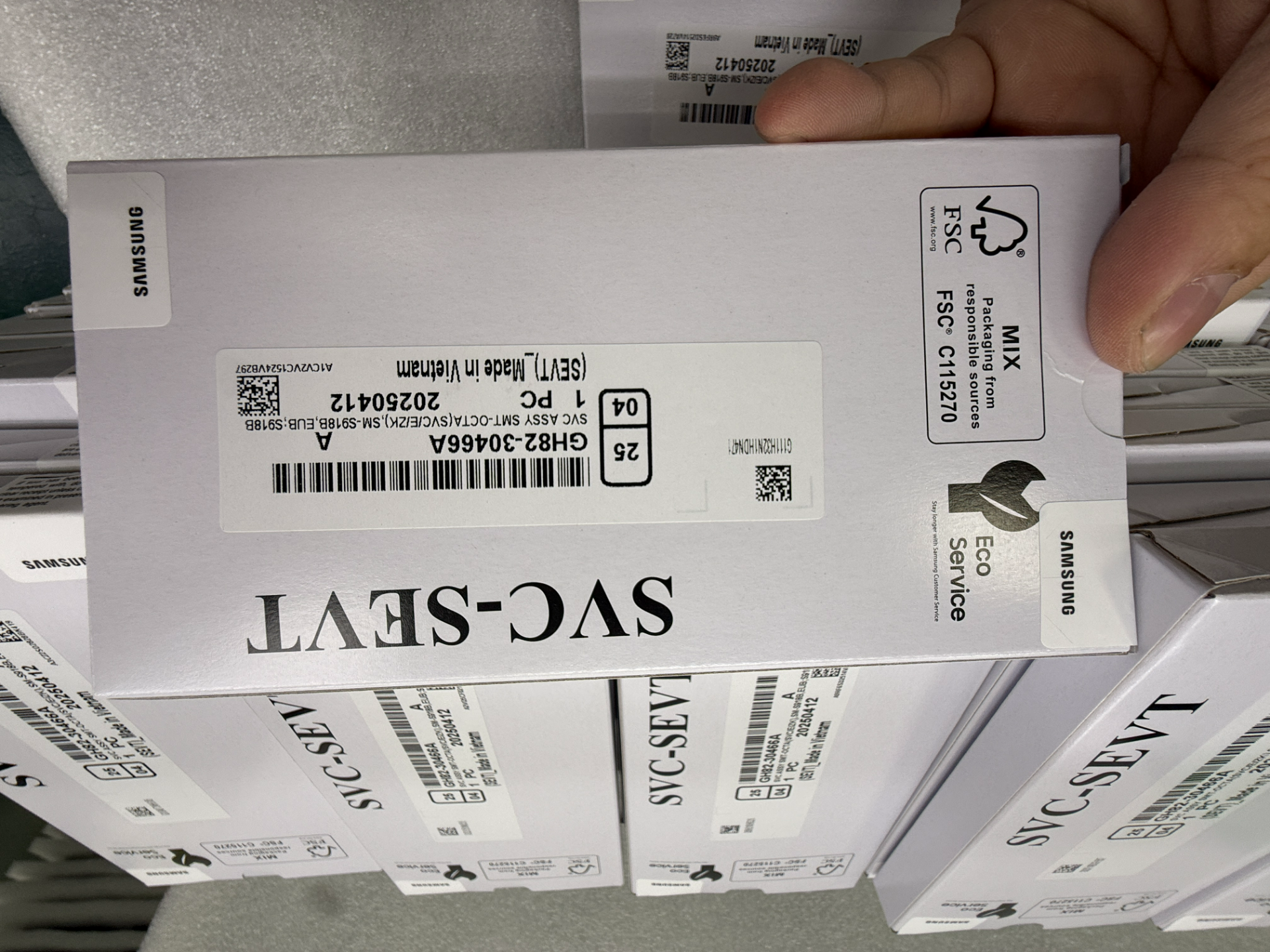

Choose the service level that fits your supply chain: you can provide components and let our technicians perform precision integration under strict quality protocols, or let our procurement and production teams source authentic display modules and mid-frames, handle assembly, perform extended testing, and deliver ready-to-sell units. Throughout production, traceability is enforced — every batch is logged with serial references, inspection photos, and stage-by-stage checklists so you can audit performance and warranty claims with confidence.

Quality control is built into every step. Incoming materials are verified, fixtures are calibrated, and controlled-environment benches reduce particulate contamination and alignment drift. Our engineers follow official service guidelines and add enhanced durability and alignment audits that reduce field failure risk. Functional testing covers power, display uniformity, touch responsiveness, and mechanical stress sampling. Those rigorous processes are what differentiate our assembly line and reduce downstream returns.

We know throughput and predictability matter. With a flexible daily capacity of 500–1,000 units (depending on model and configuration), we accommodate small repeat orders and larger runs with transparent scheduling. Clients receive daily production updates, pre-shipment QC reports, and photographic verification on request. Our Hong Kong base shortens transit times to Europe, the Middle East, and the Americas while simplifying export compliance and customs processing.

We know throughput and predictability matter. With a flexible daily capacity of 500–1,000 units (depending on model and configuration), we accommodate small repeat orders and larger runs with transparent scheduling. Clients receive daily production updates, pre-shipment QC reports, and photographic verification on request. Our Hong Kong base shortens transit times to Europe, the Middle East, and the Americas while simplifying export compliance and customs processing.

To deliver consistent product finish and reliable markets performance, our production workflows include precision alignment jigs, torque-controlled fastenings, anti-static handling, and adhesive-bonding validation. Beyond standard checks, we use random-sample lifecycle cycles to validate long-term reliability and warranty claims handling. This attention to detail ensures your products meet retailers’ fit-and-finish expectations and end users’ durability demands.

Cost and risk reduction are core benefits of partnering with us. The assembly-only option minimizes your sourcing margins while preserving professional integration and QC. The full turnkey path consolidates procurement, reduces landed cost through supplier partnerships, and removes logistics friction for clients that prefer an end-to-end supply solution. Either approach is supported by documented SOPs, KPIs, and flexible service-level agreements tailored to your commercial goals.

We support aftermarket operations as well: reverse logistics, warranty repair batching, EOL defect analysis, and inventory consignment are standard options. For clients who need private labeling or specialized packaging, our packaging line can be configured for retail-ready or repair-kit shipments. For customers worried about field reliability, our engineers will collaborate on test plans and acceptance criteria before the first pilot run.

We support aftermarket operations as well: reverse logistics, warranty repair batching, EOL defect analysis, and inventory consignment are standard options. For clients who need private labeling or specialized packaging, our packaging line can be configured for retail-ready or repair-kit shipments. For customers worried about field reliability, our engineers will collaborate on test plans and acceptance criteria before the first pilot run.

Communication and transparency are promises we keep. Before production begins we provide assembly SOPs, inspection criteria, and target KPIs; during runs we supply live status and QC evidence; after shipment, our support team handles follow-ups and defect analysis. That client-first approach is why many international partners return to Luoyi Technology again and again.

For companies that value reliability and operational control during Samsung LCD assembly, Luoyi Technology delivers a proven combination of skilled technicians, scalable throughput, and comprehensive quality documentation. Whether you are launching a new SKU or scaling repair operations, our team will help you reduce time-to-market and protect your brand reputation.

For companies that value reliability and operational control during Samsung LCD assembly, Luoyi Technology delivers a proven combination of skilled technicians, scalable throughput, and comprehensive quality documentation. Whether you are launching a new SKU or scaling repair operations, our team will help you reduce time-to-market and protect your brand reputation.

Ready to move forward? Request a sample evaluation, get a formal quote, or schedule a walkthrough of our SOPs. Contact our sales team today to discuss timelines, pricing, and pilot quantities — and experience how dedicated engineering and repeatable processes turn tight tolerances into dependable products. Partner with Luoyi Technology for premium integration and robust supply chain support on every project, including Samsung LCD assembly before your next market roll-out.

Reviews

There are no reviews yet.